MABRs (or membrane-aerated biofilm reactors to you and me)

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

The membrane-aerated biofilm reactor (MABR) seems to be the new kid on the block, with just a few commercial technologies around and, it seems, just one or two full-scale installations (though there have been large-scale demonstration trials).

Except that it really isn't that new. The term 'MABR' was first introduced around 20 years ago by Mike Semmens of the University of Minnesota. The large body of research on 'regular' aerobic, and subsequently anaerobic, MBRs at Cranfield University was actually preceded by a collaborative research programme on MABRs between Tom Stephenson of Cranfield and Semmens in the early 1990s.

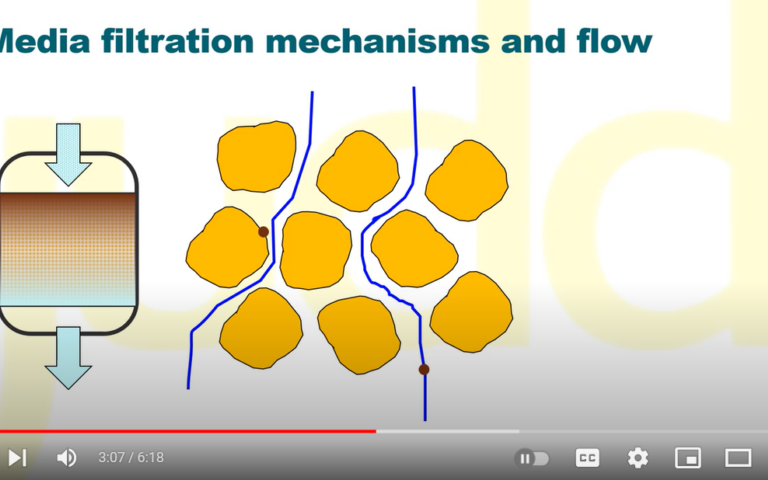

The original work was based on a pure oxygen fed technology, which attracted the interest of gas suppliers like Air Products. As with the most recent technology, pretty much all of the oxygen introduced to the bioreactor via the membrane is utilised by the microorganisms because it is introduced in molecular (or 'bubble-less') form. Because a biofilm is formed on the membrane itself, the oxygen seems to go straight into biomass; the usual mass transfer limitations, which limit the standard oxygen transfer efficiency to somewhere between 10 and 40% in conventional fine bubble diffuser aeration (FBDA), no longer apply.

So, what's not to like? The ~100% efficiency of oxygen utilisation is the big selling point of the technology. Even if air is used as the feed instead of oxygen − which means five times as much gas is pumped but it is a free source rather than coming with a price tag − there is bound to be some aeration energy cost saving compared with FBDA.

There are a few things to consider when the membrane is used for aeration. Firstly, and most obviously, using the membrane in this way means that there is no longer any membrane-based biomass separation. If the perm-selectivity properties of the membrane are needed to produce a clarified effluent, an additional membrane separation stage is required for this.

Secondly, even given the significant reduction in membrane cost over the past 25 years or so, membranes are unlikely ever to cost less than a simple FBD − which is not so different to something that would be dropped into a fish tank − or even the more advanced high-shear aeration devices.

Thirdly, membranes have a finite life − as, indeed, do FBDs but the latter are cheaper so the replacement cost is less onerous. Since commercial membrane aerators are still fairly new and there are few and only very recent installations, the membrane life is currently unknown.

Fourthly, FBDA does more than just oxygenate the mixed liquor. The fine bubbles also provide a degree of mixing, which is lost when the oxygen is introduced in molecular form. Membrane aerators must therefore always require supplementary mechanical mixing, though this doesn't necessarily add greatly to the cost since mechanical mixers are often used in conjunction with FBDA. However, FBDA is effective in limiting the collection of solids at the base of the aeration tank.

newsletterSignup is not templated

Lastly, a key aspect of the MABR is the growth of a biofilm on the membrane surface, which expedites the high oxygen utilisation. The biofilm cannot be allowed to grow in an uncontrolled manner since it would eventually fill the membrane channels, clogging them. The membranes must therefore be regularly cleaned. Again, this isn’t exactly a showstopper: both conventional MBR biomass separation membranes and FBDs require cleaning, but it is another consideration.

So, will membranes displace FBDs? Will ceramic membranes displace polymerics? I’m asked these and similar questions on a fairly regular basis and the response is always: if I knew the answer to such things, do you think I’d be doing this job?

The answer to that question is much more straightforward. No, I’d be reclining on a beach somewhere in the Maldives, sipping iced diet cola, with Mrs Judd sat next to me (probably checking the analytics on her web site).