The cost of ceramic membranes for MBRs

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

If there’s one subject which seems to divide opinion pretty sharply in the membrane and water treatment community, it’s the role and future of ceramic membranes. That’s assuming, of course, that people do have an opinion on the subject and that this opinion is based on a degree of acquired, contemporary knowledge.

And there’s the rub. As with so many other things in water and wastewater technology, what was the case 3−5 years ago, or even last year, isn't necessarily the case today. Most people familiar with membrane technology who haven't perhaps scrutinised the most recent developments might have assumed ceramic membranes to be too expensive to displace polymeric materials.

It was the same in the past about the likelihood of MBRs displacing SBRs as a viable small-footprint wastewater technology. I remember Tony Fane − the daddy of all membrane scientists − recalling the time he was sat in the audience listening to the pioneering Kazuo Yamamoto explaining how a hollow fibre membrane could be placed in a conventional activated sludge (CAS) tank to produce clean water. 'This', the great man mused, 'will never work'. That was in the late 1980s, and Tony’s true greatness is reflected in the fact that (a) he’s prepared to recount this anecdote, and (b) freely confesses how wrong he was.

Ceramics and OPEX

And so to ceramic membranes. Surely, they're just too damned expensive, aren’t they? Well, as someone who’s dabbled in cost analysis every once in a while, let’s just run through the process for operating expenditure (OPEX).

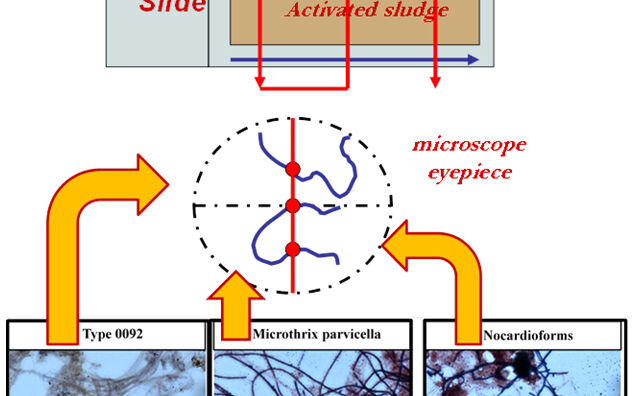

The OPEX of an immersed MBR (iMBR) process is largely down to the ratio between membrane air scour rate and the flux (MBR OPEX − the theory of running costs). The other key factors are the membrane life and its cost. There’s also cost of aerating the biological tank to keep the microorganisms alive, and treating the organic matter like an all-you-can-eat-buffet, but the same sort of factors apply to this part as for any other MBR (or indeed a CAS).

So, the membrane replacement component of the OPEX is then approximately proportional to the ratio of the membrane cost (L) to the net flux (J) times the membrane life (t): OPEX ∝ L/(J t). This means that, as far as the cost effectiveness of the ceramic membrane compared with the polymeric one is concerned, the determining factor is the ratio of the term L/(J t) for the two materials. For example, if the ceramic material costs four times as much but lasts twice as long and operates at double the flux of the polymeric material, then there is parity of the OPEX between the two materials.

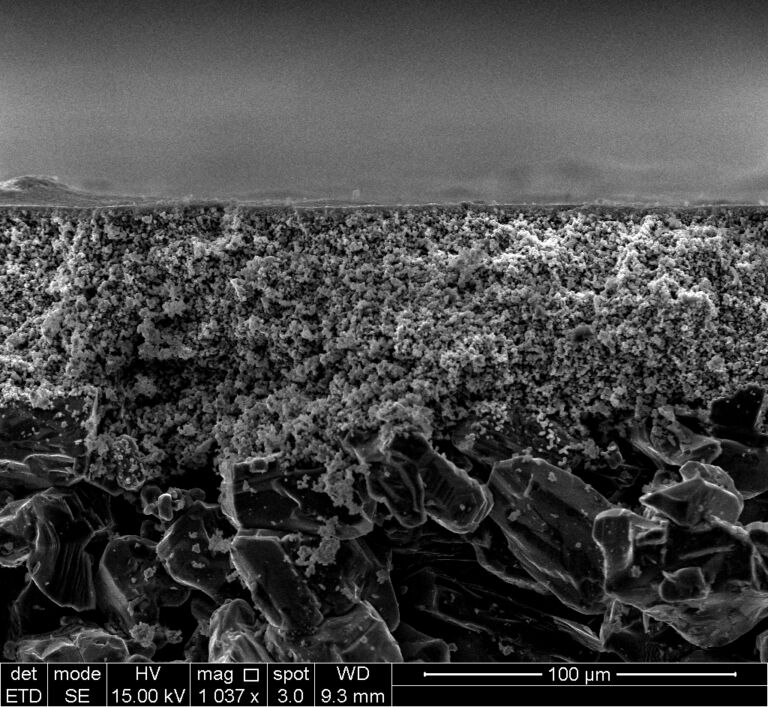

There aren’t yet a huge number of reference sites for ceramic MBRs, particularly for the newer flat sheet (FS) configuration. The sidestream multitube configuration (sMT MBR) has been around for a while and appears to have carved a niche treating challenging industrial effluents, those perhaps at elevated temperatures and/or containing solvents, which might otherwise cause problems for conventional polymeric materials.

However, a wet-finger-in-the-air estimate of the ceramic:polymeric flux ratio − partly based on the outcomes of the high-profile Jurong study where a ceramic FS MBR was used to treated anaerobically-treated industrial effluent − would be 1.3−1.5. It can also be reasonably assumed that ceramic membranes will outlast polymeric ones − perhaps by at least a factor of two (provided there’s no grit in the water to abrade the membrane surface).

Ceramics and cost

Which then naturally leads to the next question: How much does a ceramic membrane cost? Like many such questions about cost (and, in some instances, people’s age) it’s a sensitive topic. What is generally known is that ceramic membranes always used to cost hundreds − or even thousands − of dollars per m2 at a time when polymeric membrane costs had dropped into double figures on the same basis.

However, it now appears that the ceramics have become dramatically more cost competitive − perhaps below that $100 m-2 threshold − and are likely to continue the downward trend in price for much the same reasons as polymeric MBR membranes did throughout the nineties and early noughties. It is an immutable natural law: if the demand is there, the price tends to fall due to a combination of economy of scales and improvements in manufacturing methods.

A few companies have been prepared to dip their toes in this particular water. Within the last six years or so, five commercial ceramic flat sheet MBR suppliers (Cembrane, Ceraflo, ITN, LiqTech and Meiden) have arisen, alongside the more established ceramic multitube MBR technology suppliers (like Likuid Nanotek). There’s also, rather intriguingly, even the prospect of creating a ceramic membrane MBR from waste materials, as being investigated by the Recycled Membrane Bioreactor project (REMEB), funded by the European Commission.

The trajectory of ceramic membrane MBRs is a truly absorbing phenomenon, and one which could potentially change the landscape of MBR technology. As with so many things in life, though, you get what you pay for. You just need to know how much you’re paying.