A comparative techno-economic-environmental assessment of full-scale CAS vs MBR technologies

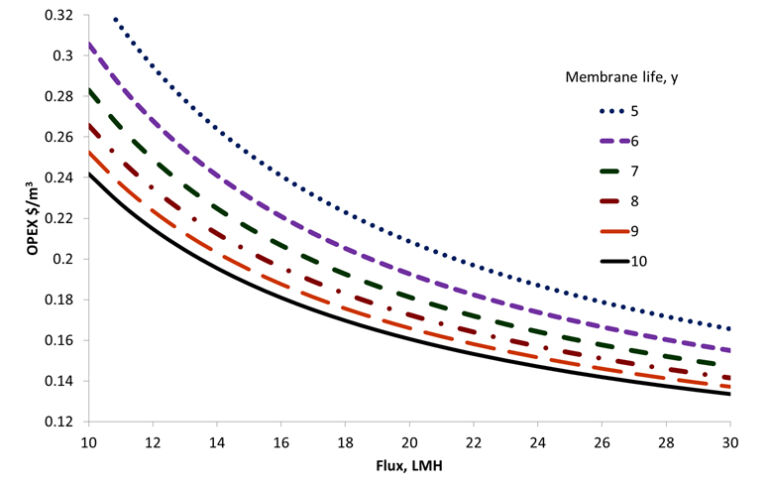

A number of studies have compared MBR system performance with that of the conventional activated sludge (CAS) process in treating municipal wastewater but none have yet compared their environmental, techno-economic and social acceptance aspects.

Read article