The 2015 MBR Survey results

Simon Judd and Claire Judd

In the third of our completely unscientific surveys of MBR practitioners, Simon Judd − author of The MBR Book − and Claire Judd − Manager of The MBR Site − discuss the results

In February 2015, we asked you to contribute to our MBR survey, with a view to sharing knowledge and experiences about the common technical issues that prevent MBRs working as they should, as well as your views about the future for MBR technology.

We are pleased to report that 186 people gave up their time to respond to the survey: a big 'thank you' to all those who took part, in particular because the large number of respondents goes some way to validating the common themes that emerged from the analysis of the results.

Overview

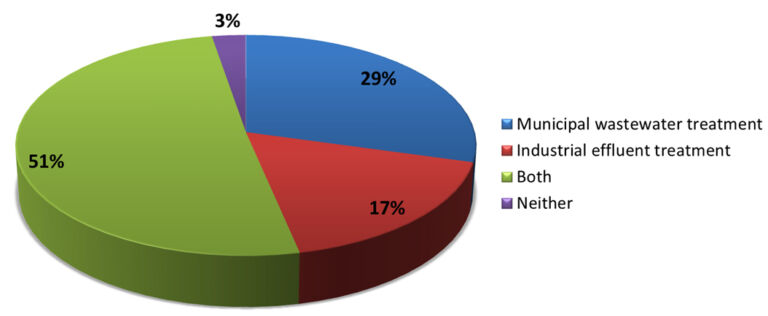

The latest survey attracted 186 responses. This compares with 69 responses received in our survey of January 2012, and 48 responses in our survey of February 2010. About half of those who contributed felt that their responses applied to both municipal and industrial wastewater treatment (Fig. 1). 17% considered their answers to be more specific to industrial effluent, 29% specified municipal wastewater, and 3% felt their answers related to neither municipal nor industrial wastewaters.

Around a quarter of the respondents were membrane technology suppliers and at least 15% were academics. Only around 5% were end users. Many of the remainder were contractors or consultants.

Question 1: In your experience, what are the main technical issues or limitations that prevent MBRs working as they should?

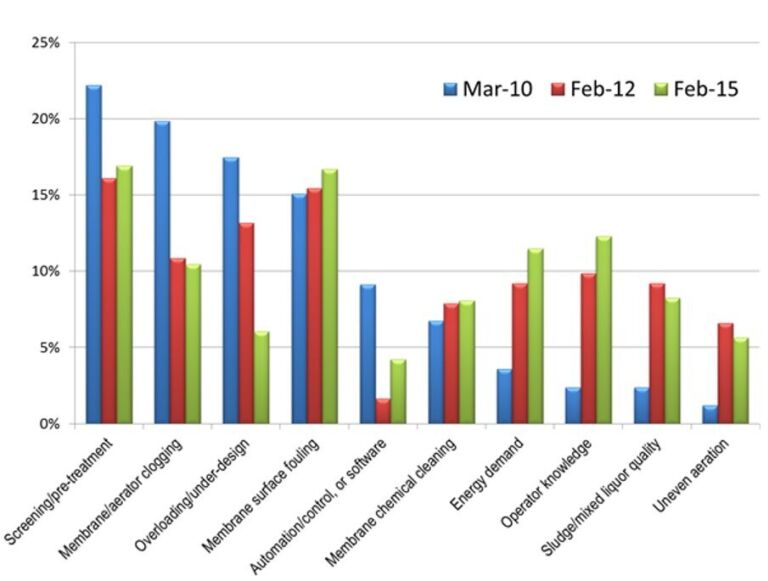

The latest survey was based on the same question and the same set of elective answers as our survey of February 2012. The 2015 survey included an additional ‘other’ option, which accounted for 5% of the responses: the calculated percentages for the other 10 responses were normalised (i.e. divided by 0.95) to account for this. The original 2010 survey comprised an open question with a free response and the responses provided were used to formulate the answer options for the subsequent surveys.

The most striking feature of the 2015 survey, compared with our 2012 MBR Survey, is the similarity in the responses (Fig. 2). Indeed, all categories other than ‘overloading/underdesign’ were within 2% of the 2012 survey responses.

As with the previous survey, the combined total for ‘screening/pretreatment’ and ‘membrane/aerator clogging’ was comparable to that of ‘overloading/underdesign’ and ‘fouling’. As pointed out by some respondents, both to this survey and the previous two, clogging is associated with insufficient pretreatment, and both fouling and clogging can arise from overloading. It can be therefore be concluded that, as with the previous two surveys, clogging of either the membrane channels or aerators remains as great a problem as membrane surface fouling.

The only issues for which the absolute rating has increased by more than 2% (i.e. they are seen as more of an issue now than in 2012) were ‘operator knowledge’ and ‘energy demand’. The focus on improved membrane air scour efficiency by some of the technology suppliers is thus vindicated by this survey, as is the perhaps the abundance of MBR training courses.

24 respondents provided additional comments, some of which were quite extensive, provided in the ‘other’ category for Question 1. In our analysis, these have been combined with the responses to Question 3 (another open question) and are discussed further below.

Question 2: In your opinion, how will MBR technology develop in the future?

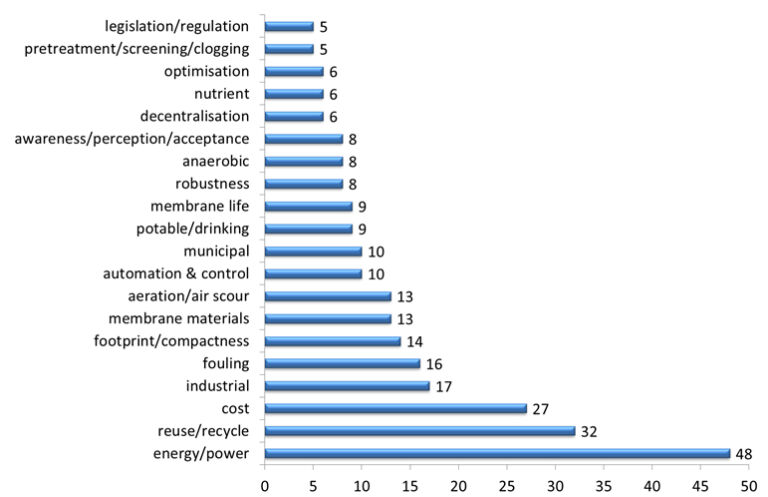

This was the first year this question had been asked in our survey and, perhaps unsurprisingly, it generated some expansive responses. The total word count from all compiled responses was 3960 − about the length of an average peer-reviewed research article. Condensing all the comments was challenging, but analysis of the 20 most-used words across all 151 responses reveals that ‘energy’ and ‘cost’ (obviously related) occupy two of the top three positions (Fig.3).

In terms of applications, water reuse features strongly. Also, industrial applications feature more prominently than municipal, perhaps reflecting the overall larger number of opportunities, albeit with smaller flows. Key aspects such as nutrient removal and decentralisation also feature in the responses.

Other key terms identified include ‘legislation’, ‘optimisation’ and ‘perception’ − encapsulating a key driver, challenge and barrier to the technology in three single words. ‘Process automation/control’ and, most prominently, ‘footprint/compactness’ also featured as frequently-used terms. While ‘footprint’ is a recognised driver for implementation, improved process automation and control is arguably one of the key aspirations for MBR technology. Sustaining the membrane flux at the lowest energy expenditure implies that applied shear (through membrane aeration or crossflow operation) must be adjusted accordingly. The identification of new membrane materials relates partly to the new ceramic technologies, but also to the perceived requirement for more robust and antifouling materials. Reference to anaerobic technology again relates largely to minimising energy demand, as well as sludge production: there appears to be a strong sustainability element underpinning many of the responses.

The analysis does, however, also throw up a few surprises. Despite identifying ‘clogging’ as being at least as important an issue as ‘fouling’ in Question 1, respondents refer far more to the development of antifouling membranes than to clogging amelioration in Question 2. Against this, ‘aeration’ (including membrane air scour) features as often as ‘membrane materials’ in the responses. Most surprisingly, identified applications include potable water, which seems somewhat ambitious. As well as the specific technical aspects of envisaged future developments, a number of respondents expressed general confidence in the future of MBRs.

Question 3: Do you have any other burning comments about MBRs that you wish to raise?

It is challenging to crystallise all the responses but it appears that, as well as determining the future of MBRs (Fig. 3), ‘cost’ and ‘energy’ also to a large extent jointly represent the biggest bug-bears of the technology. Defenders of MBR cost appear to be in a distinct minority, though it is pointed out that total cost analyses can favour MBRs over classical technologies − as indicated by reports from a number of different groups (see The MBR Blog: MBR cost determination). So long as a high level of nutrient removal is required and/or the water is for reuse purposes (and in particular if it is to undergo reverse osmosis), an MBR is almost certainly likely to be lower in CAPEX than a classical process.

A number of anecdotal aspects identified by individual respondents have been summarised below:

- Standardisation: It remains unclear − as it has done for many years − as to whether MBR membrane technologies will become standardised to aid interchangeability, despite the wishes of some of the end users.

- Education: The lack of familiarity of end users and contractors with the technology, particularly in developing countries, is a significant barrier to successful implementation.

- Information: More extensive case study information from established installations is needed to encourage implementation.

- Piloting: As with many water/wastewater treatment technologies, it is highly desirable to conduct pilot trials prior to installation but there is rarely the time or budget for this.

- Alternative technologies: Other new/novel technologies, such as the moving bed bioreactor, offer a viable alternative to MBRs for some applications.

- Degassing of permeate: Desorbed gas in permeate extracted under suction must be removed by an air−liquid separator on the permeate side.

- Disinfection capability: The ability of MBRs to disinfect in water recycling schemes has not been accepted in some countries, such as Australia.

- FOG: Fats, oils and grease remain a concern for MBRs due to the naturally hydrophobic nature of the membranes.

- Screens management: Screen ratings of 0.8 to 2 mm imply very significant quantities of screenings demanding further management.

- Integrity testing: Pressure decay tests cannot be used for flat sheet membranes.

And finally…

The range of respondents was very broad, with extensive collective practical experience of MBR technology, suggesting that their responses are a reasonable reflection of the status of the technology from a practitioner viewpoint. The similarity in the weightings of responses across the various topics between the 2015 survey and the survey of three years ago suggests that there has been little change in the relative importance of the main challenges. Against this, evidence provided by the ever-increasing number and size of the installations − the prospective installations at Canton in Ohio and Henriksdal in Stockholm will have projected peak flow capacities of 333 and 864 MLD respectively − strongly suggest that confidence in the technology is increasing, and that the challenges identified in the survey are far from insurmountable.