Really cleaning up − clogging in MBRs

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

Having spent the best part of the past 6−7 years bemoaning the lack of understanding of clogging of MBR membrane channels (and having a succession of research proposals on the subject routinely rejected), it is with a certain amount of pride, satisfaction and − let’s face it − insufferable smugness that not one, not even two, but THREE papers on the topic have been proffered by the group at Cranfield.

It cannot be claimed that these are the first publications in the peer-reviewed literature in this area, a claim which could rightly be made by Prof Alain Grasmick’s group at the University of Montpellier II for their enlightening article published in Water Science and Technology in 2009. However, over the past two years the Cranfield group has provided an insight into ragging (Stefanski et al, 2011), cleaning and desludging (Zsirai et al, 2012) and sludging itself (Buzatu et al, 2012).

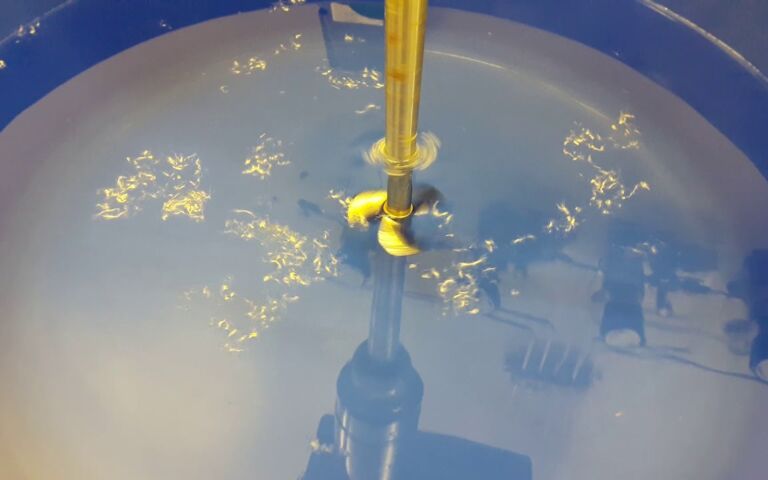

In the last article (Buzatu et al, 2012), the degree of clogging was painstakingly measured by manually removing the sludge from the fibre bundles, a task undertaken with commendable diligence (and, one suspects, a certain bleak resignation) by the researchers Pompilia Buzatu, Sara Gabarron and Tamas Zsirai.

Whilst the degree of clogging varied significantly, for no obvious underlying reasons, it was clear that clogging played as big a part in permeability suppression as fouling and, predictably enough, was not significantly impeded by regular chemically-enhanced backflushing. Moreover, of all the cleaning methods studied in the earlier paper (Zsirai et al, 2012), declogging provided the greatest instantaneous permeability recovery, though subsequent permeability decline followed.

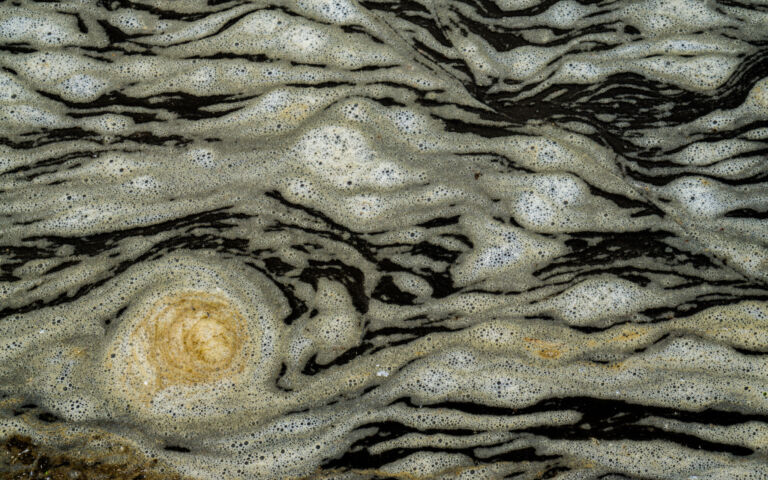

Finally, Stefanski’s paper from last year appears to point to cotton wool as being primarily responsible for ragging, with tiny filaments apparently able to agglomerate to form long braids in the membrane tank − yet another fine verification of Murphy’s Law.

So, what does all this mean?

So, what does all this mean? Clearly if sludge passes through a membrane channel then it must necessarily be dewatered to some extent. If dewatering is sufficiently great, and the crossflow of solids insufficiently fast, then there is a risk that these solids will be retained within the channels.

Moreover, if the solids are naturally more 'sticky' or else have some other property that makes it more likely that the particles will agglomerate, then it would be expected for this to exacerbate sludging. Against this, sludges which are perhaps of classically higher quality may be less susceptible to sludging. Nonetheless, it is apparent that solids which are retained in the membrane channels can only be removed by physical intervention − as will be familiar to a number of operators and, in her case in the interests of expanding our knowledge and understanding, Ms. Buzatu and her colleagues.

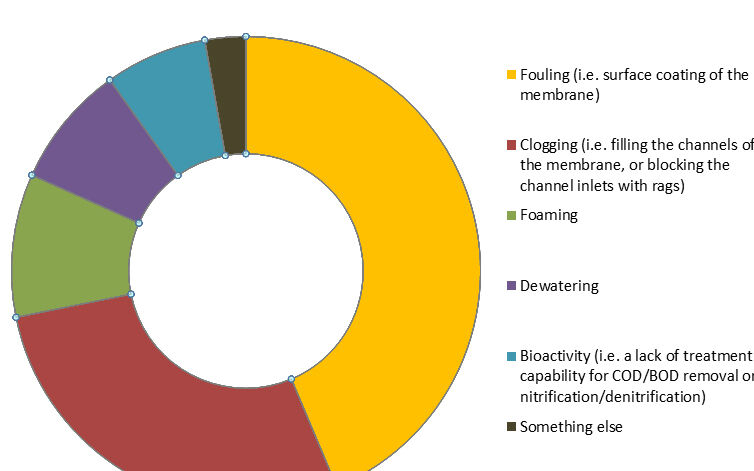

And what now for research and development into MBRs? Well, there is clearly still much to do. The clogging issue is just one issue, but one apparently identified as being a significant limiting factor in a survey of practitioners earlier this year.

However, as has been said by many before, there is more to R&D than science. There is also engineering − a discipline which cannot be ignored, even by a (severely lapsed) chemist such as myself. In the case of MBRs, amelioration of sludging and ragging demands a solution based on engineering of the process, either to maintain a high sludge quality or to dislodge the solids before they become irreversibly adhered to the membrane.

And who knows what form this should take? Chemical destabilisation, vibrating membranes, or perhaps an enormous, intermittent blast of air …