A good polish − the case for MBRs

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

There continues to be a debate over whether MBRs really are worth the money, when a biotreatment plant with a micro/ultrafiltration polish would suffice.

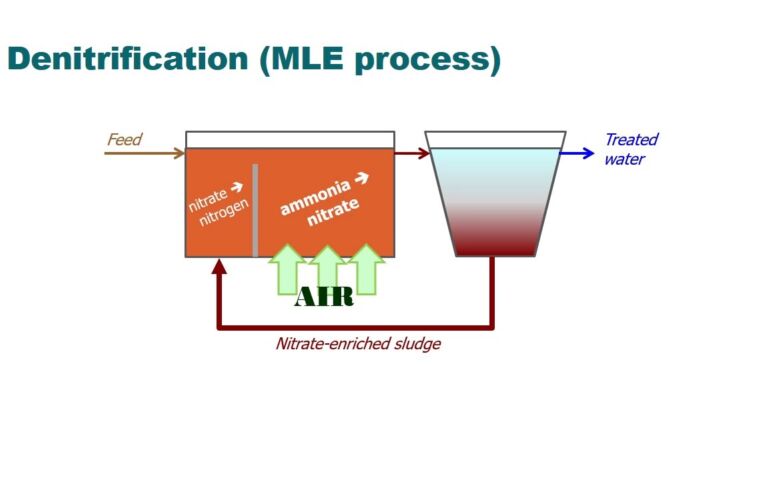

There are all sorts of factors at play here. An MBR provides biotreatment and membrane filtration in a single stage (though still demanding two tanks). Because MBRs operate at higher sludge concentrations than a conventional ASP with secondary clarification, they occupy a lower footprint. However, it’s challenging to get the specific energy demand much lower than about 0.65 kWh/m3. They also generally need a weekly CIP.

Contrast this with polishing plant, the most optimum of which would weigh in at less than 0.2 kWh/m3, with the biotreatment less than 0.35 kWh/m3 making a total of 0.55 kWh/m3. What’s more, a polishing plant will always operate at a higher flux − perhaps 50−100% higher − which makes polishing even more cost effective since as little as half the membrane area is required. So, no question about it, polishing wins hands down.

Or does it?

For one thing, these figures are not hard-and-fast. Some UF polishing plants operate at over 1 kWh/m3, either because they operate at higher pressure or are challenged with a more highly-fouling feed water. Similarly, some older or oversized MBRs can operate at well over 2 kWh/m3, especially during off-peak flow periods. Secondly, there's the impact of footprint and sludge production − both of which tend to be lower for the MBR than for a polishing system.

MBRs appear also to provide slightly better dissolved organics removal, which can have a bearing on the sustainability of any downstream reverse osmosis plant. Lastly, there’s membrane life. There is an argument that the more benign fluxes at which MBRs operate provide a longer life, though there is no evidence that the supplier warrantees differ significantly between the two applications.

So, which is cheaper? Take your pick. As with so many things in life, we believe what we want to believe − unfettered and unperturbed by the tiresome distractions of data, evidence and fact.