Membrane materials used in MBR technology: polymeric and ceramic

Polymeric and ceramic membrane materials

A membrane as applied to an MBR is simply a material that allows water and dissolved matter to pass through it while rejecting solid particulate materials. It is ‘perm-selective’, with the degree of selectivity depending on the membrane pore size.

In the case of MBRs, the range of pore sizes is relatively small, ranging from the microfiltration (MF) range of 0.1−0.4 µm, to the coarse ultrafiltration (UF) range of, generally, between 0.02 and 0.1 µm.

There are mainly two different types of membrane material: polymeric and ceramic. To be made useful, the membrane material must be formed − or configured − in such a way as to allow water to pass through it. A number of different polymeric and ceramic materials are used to form membranes.

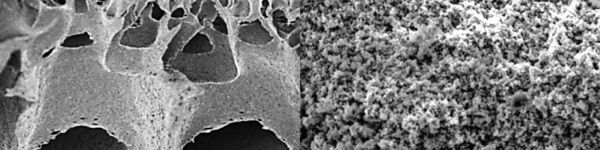

Membranes generally comprise a thin surface layer which provides the required perm-selectivity on top of a more open, thicker porous support which provides mechanical stability.

| PAN | Polyacrylonitrile |

| (HD)PE | (High density) polyethylene |

| PES | Polyethylsulphone |

| PS | Polysulphone |

| PTFE | Polytetrafluoroethylene |

| PVDF | Polyvinylidine difluoride |

| Al2O3 | Aluminium oxide / Alumina |

| SiC | Silicon carbide |

| TiO2 | Titanium dioxide / Titania |

| ZrO2 | Zirconium dioxide / Zirconia |

Membranes are usually fabricated to:

- have a high surface porosity, or % total surface pore cross-sectional area,

- have a narrow pore size distribution to provide as high a throughput and selectivity as possible, and

- be mechanically strong to give structural integrity.

The material must also normally have some resistance to thermal and chemical attack, that is, extremes of temperature, pH and/or oxidant concentrations that normally arise when the membrane is chemically cleaned.

The material should also ideally offer some resistance to fouling, i.e. the reduction in permeability caused by constituents (foulants) in the mixed liquor depositing on either the membrane surface or within the membrane pores. Since the polymers used are all hydrophobic (i.e. 'water hating') they all have a tendency to be fouled by the similarly hydrophobic organic matter in the mixed liquor. They therefore require 'wetting out' before use. Wetting out defines the process by which water is forced into the membrane pores.

Ceramic versus polymeric membrane materials

While ceramic membranes are more robust in terms of resistance to fouling and chemical attack, they remain limited to niche applications in MBR technology − primarily due to their relatively high cost.

Ceramic multichannel ‘monoliths’ have found use in some applications, and recently ceramic flat sheet configurations have been introduced for immersed MBR technologies. However, commercial MBR membranes are almost all polymeric.

More than half of the MBR membrane module products offered on the market are based on polyvinylidene difluoride, or PVDF. Other less common membrane materials include polyethersulfone (PES) and polyethylene (PE). The combination of good chemical resistance, controllable pore size, and a relatively high mechanical strength, coupled with good flexibility, has meant that the PVDF products dominate.

The polyolefinic membranes (such as low-density polyethylene, LDPE) are among the lowest in raw production cost of all MBR membrane materials, the pores being generated simply by extruding that material under controlled conditions (or ‘dry spinning’) to produce slit-like pores. This slit-like pore structure is to be distinguished from the more complex thermal induced phase separation (TIPS) process for PVDF, which produces the more classic pseudo one-dimensional pores. The remaining materials − polyacrylonitrile (PAN), polysulphone, polyvinyl alcohol (PVA) and polytetrafluorethane (PTFE) − are much less common.