MBR costs − an overview

Are MBRs expensive?

MBRs are sometimes seen as expensive options and it is true that membrane bioreactor systems are not always the cheapest or most appropriate choice of technology for some circumstances. A full needs analysis is required, first of all to confirm that an MBR will be the most cost effective solution for a particular requirement, taking everything into account.

There are a number of cost factors, as well as other considerations, to take into account when considering implementing MBR technology. These include:

- capital cost (CAPEX)

- operating cost (OPEX)

- overall cost or carbon footprint

- size

- robustness

- residuals and environmental impact.

The trade-off between capital and operating costs is well recognised. Often, greater investment in capital equipment can increase the process robustness (for example through control measures) and therefore decrease maintenance and repair costs.

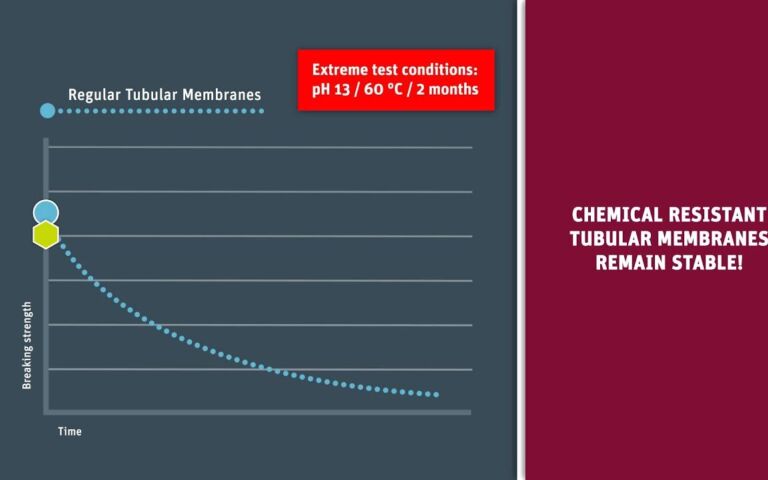

In the case of a membrane process, this is demonstrated by the selection of the design flux. Higher fluxes permit reduced capital costs through the correspondingly reduced membrane area requirement. However, this then increases the likelihood of fouling, demanding more frequent cleaning and increasing the process downtime.

Costs and definitions

For very large flows of water of well understood characteristics − and ease of biotreatment and processing overall − the primary driver is cost, both CAPEX and OPEX.

Provided whole-life MBR costs are considered, then the net present value (NPV) in units of USD/m3 treated water provides a reasonable indication of overall cost, NPV being a function of CAPEX, OPEX and the plant life and residual end-of-life value.

The two key components of OPEX (ignoring labour) are the energy demand and membrane replacement. Chemicals costs are normally relatively small. Energy demand primarily relates to aeration and sludge transfers, with permeate production also demanding energy to differing extents depending on the configuration of the MBR process. If energy demand is also normalised against permeate production (i.e. the specific energy demand, or SED, in kWh/m3), then a key OPEX-determining parameter is the volume of air demanded per unit volume permeate. This then takes units of Nm3 air − ‘Nm3’ being the air volume at a standard temperature (of 20°C).